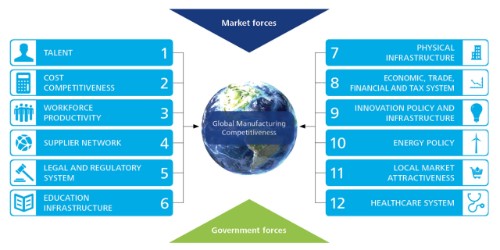

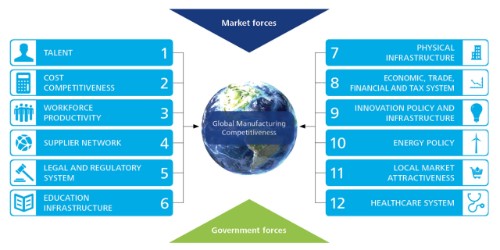

According to Deloitte’s 2016 Global Manufacturing Competitive Index, talent is the #1 driver of competitiveness.

The issue of how to build a steady pipeline of manufacturing talent is one that our thought leaders continually address.

The problems are well-established: we are living in a mature economy, and within the next 10 years, the baby boomer generation, on which our manufacturing sector was built, will retire. The generation coming into the workforce is less interested in a career in manufacturing. On top of these shifting demographics, the technical landscape in manufacturing is evolving so much that there is a tremendous skills gap. “By 2024, we will have three generations on the shop floor with completely different value sets, interests, abilities… and this is a huge challenge for leadership, team dynamics, and incentives,” says Dirk Hilgenberg, VP, Assembly at BMW Manufacturing.

How do our thought leaders propose we address these problems?

Change the business model

In order to stay ahead and address these problems, former VP & Head of Vehicle Assembly at FCA, Byron Greene (now VP, Manufacturing at Whirlpool), argues that manufacturing must change its business model. Curt Towne, EVP, New Business Development at TPT, agrees, giving the following statistics about the millennial workforce, which have implications for how organizations should recruit and train manufacturing talent.

- Millennials are now the single largest group within the workforce, and will soon become the biggest consumer groups, too.

- 64 percent of Millennials would rather make $40,000 a year at a job they love than $100,000 a year at a job they think is boring.

- 88 percent prefer a collaborative work culture rather than a competitive one.

- 68 percent of corporate recruiters say that it is difficult for their organizations to manage millennials.

- 74 percent want flexible work schedules.

- 50 percent do not believe that Social Security will exist when they reach their retirement age.

These values held by millennials, argues Towne, do not fit with the “old way” of manufacturing, which was tough and demanding, and leaders didn’t worry too much about motivating the workforce, since the pension was motivation enough.

“As I speak to young people across this country, I see a disturbing trend where many STEM students do not have an overwhelming desire to join manufacturing,” says Greene. “They see manufacturing as behind. Behind in technology, behind in innovation, behind in career opportunities.” He says manufacturing needs to change its business model and show the young talent that they are doing innovative things, and that they actually collaborate with many of the exciting tech companies students see as the epitome of a successful business today.

Leverage technology

Rick Davis, Vice President and Global Lead, Office of Data Acquisition and Governance, at Kellogg Company echoes this sentiment and thinks the way to solve it, and to interest the millennial generation, is to leverage technology within your organization. “Young people are way ahead of you,” he says. “They embrace technology and accept the pace of change. They come into companies expecting a level of sophistication that just doesn’t exist.”

Partner with Institutions

Many companies are dealing with this challenge by partnering with institutions to interest students in careers in manufacturing.

At FCA, they have started outreach programs as early as middle school, because they feel that the earlier they reach young people, the greater chance they have of selecting manufacturing as a career option. Davis feels similarly, and has an added challenge: “We [the Kellogg Company] are based in Battle Creek, Michigan, so we have to compete with New York and San Francisco and Chicago.” They are trying to solve this by reaching the bright kids who attend the Battle Creek Math and Science Center. They bring in speakers to talk to them about the possible career opportunities and are now offering summer internships to attract them to careers in this field.

BMW partners with several institutions to improve their manufacturing talent and innovation pipeline. For instance, they partner with Clemson University, offering a BMW Fellowship program for incoming M.S. Students, and they run the BMW Scholars Program, which allows students who are in manufacturing-related degrees to attend class full-time at local two-year community colleges while working part-time hours at their plant in Spartanburg, SC. Dr. David Cole, founder and Chairman of AutoHarvest, at our 2016 American Automotive Summit, suggested more firms should provide internship programs that fund college education in return for years of service.

This is an industry-wide challenge and Greene believes it is imperative that manufacturing companies set aside competition to ensure they all have access to a steady pipeline of talent. “We, as a collective, even in spaces where we’re in direct competition, have got to set aside initiatives to reach that talent at an earlier age.”

To join the conversation on this issue, attend one of our upcoming events:

- 2017 American Automotive Summit

- 2017 American Aerospace & Defense Summit

- 2018 American Manufacturing Summit