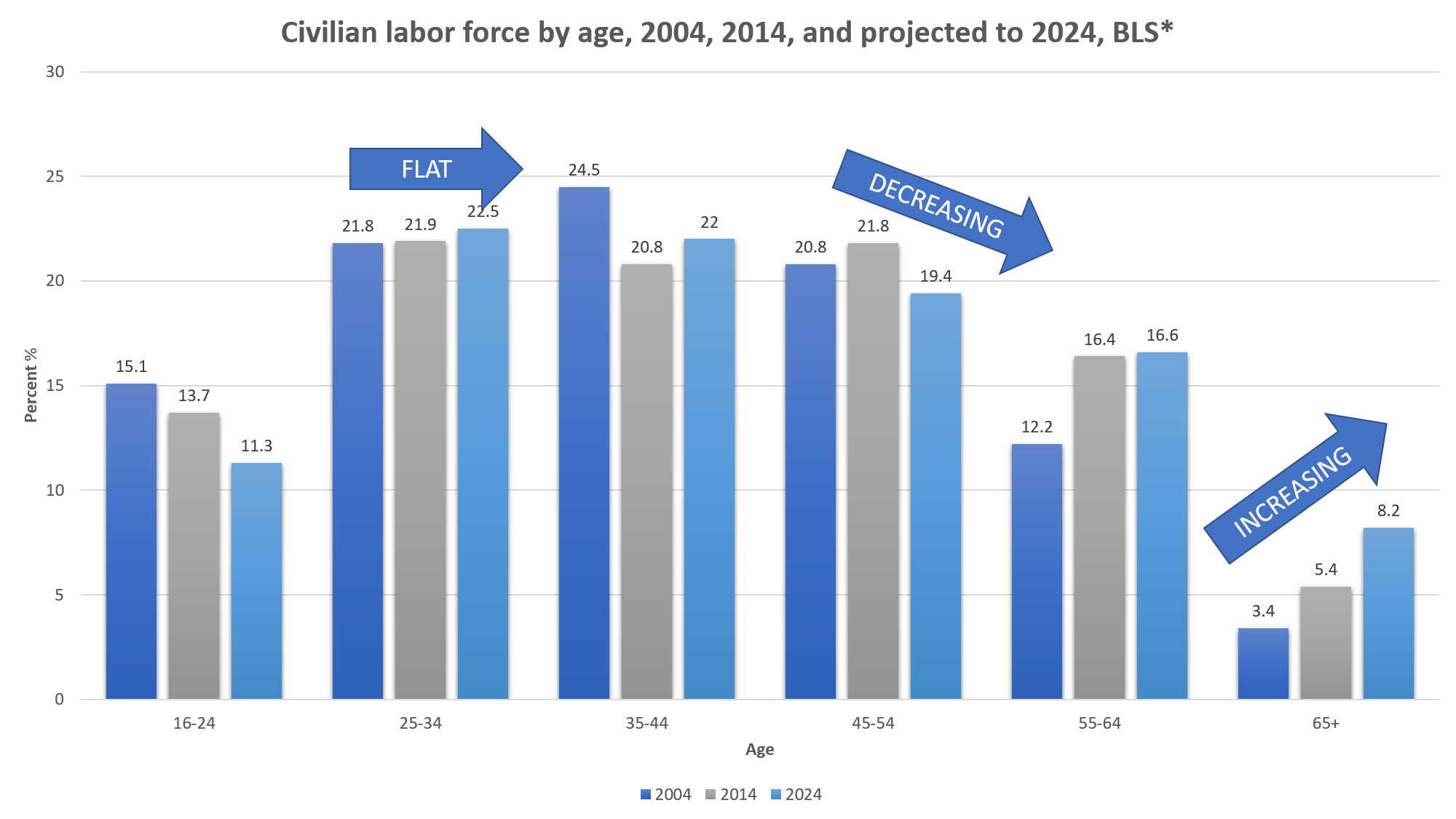

*Data source: Bureau of Labor Statistics, http://bls.gov/emp

At the American Manufacturing Summit, Dirk Hilgenberg, VP, Assembly at BMW, shared this chart showing changes in the composition of the civilian labor force from 2004 to 2024. As you can see, the population of workers age 25-34 will remain relatively stable, there will be a decline in those aged 45-54, but as some people live and work longer, there will actually be an increase of those aged 65 and older in the workforce.

The result, Hilgenberg says, is that by 2024, we will have three generations of workers on the shop floor with completely different value sets, interests, and abilities. This represents a huge challenge for leadership, team dynamics, and incentives.

Many companies are concerned with how to recruit and manage millennials in the workforce. How about the interaction between these millennials and your long-serving employees?

At the American Supply Chain Summit, Dave Malenfant, Director of the Center for Supply Chain Innovation at Texas Christian University, shared a story from his work in industry that shows how you can blend the generations to create an even more powerful organization.

Malenfant’s company had to re-organize a customer service department of about 200 people, where the average tenure with the company was 25 years, meaning a lot of people had been there 30-40 years. As Malenfant describes the problem, “That was not going to hold very long because we were about to put in a new order entry system. A lot of the current workers could not adapt to it, so we were going to go out and hire recent graduates from universities to come into the organization. The workplace was separated into pods – 4 people per pod. So we put two of the young people in a pod with two of the older people.”

“It was an absolute success,” he says. “The young people were showing the tenured employees how to learn new things in the system, and the senior people were teaching the new ones the nuances of the order entry system and the processes. Overall, we were able to increase the efficiency of the organization to the point where we could use 130 people to do the work that 200 used to do.”

Join the conversation on how to build successful teams in your organization at one of our upcoming events!

- American Manufacturing Summit | March 27- 29 | Lombard, IL

- American Supply Chain Summit | April 9-10 | Dallas, TX